Break Through Performance

Our mission is to support companies and organizations in their improvement process by engaging people to improve customer experience and to improve productivity and performance management.

Effective TPM Training at major global food company

Using the tools of TPM effectively resulted in a 30% output increase over 5 days of production, a tasty result!

Kaizen leading to OEE Overall Equipment Effectiveness of over 85% (World Class)

With growth rates of over 40% combined with very frequent product changes lots of pressure to meet the required output. On the job training combined with activities for quality assurance and quality standards the results were far beyond expectations, while the preventive maintenance could be reduced by 50%!

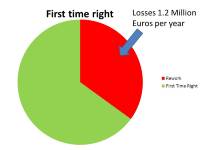

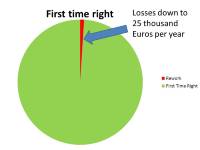

Slashing Failure Cost with more than 1 million euros

Quality is free:

Quality doesn't cost you money, it saves you money with Productivity Training

W. Edwards Deming Quality Prize

W. Edwards Deming inspired Quality in Japan, where companies achieved the highest levels of quality. Deming inspired these changes and initiated the Deming Prize creating a boost in Quality Understanding in prominent Japanese Companies to become the best of the world. Look today at Toyota, SONY, Mitsubishi, Olympus, NEC, Kyocera and many other companies.

W. Edwards Deming, Philip B. Crosby and Sir John Harvey-Jones have inspired many parts of our methodology within the process of effective change within organizations.

As a result one of our own practitioners has been supported by them both in presenting with them and been supportive in being introduced to World Class Companies within Europe and America.

Quality is Free, written by Philip B. Crosby

Who pays for defects?

Who pays for rework?

Who pays for extra inspection?

Who pays for customer complaints?

That's always the focus of our program. Elimination of Quality Failure is the most cost saving objective many companies thrive upon.

Let's focus together on creating Quality is Free in Your Organization.